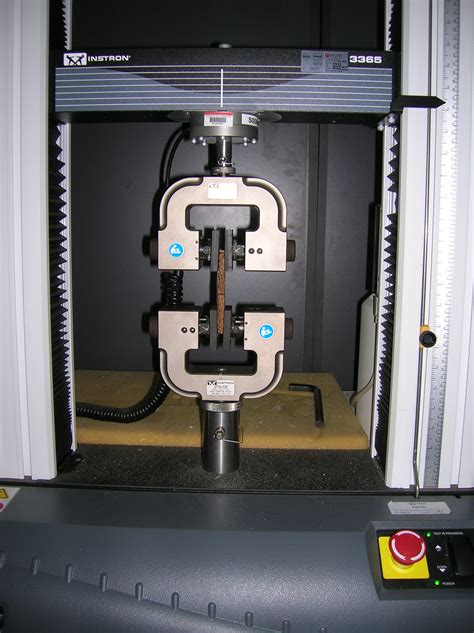

parts of tensile testing machine|tensile testing machines : vendor A Universal Testing Machine (UTM), also known as a tensile testing machine/tester, is an electromechanical testing system that applies a tensile force to raw materials or components to test for both tensile and compressive . WEB29 de set. de 2018 · About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

{plog:ftitle_list}

web21 de set. de 2018 · O Hapvida afirmou que o atendimento materno-infantil é de extrema importância, pois a operadora entende que cuidar da saúde de mães e bebês é promover também mais qualidade de vida para as novas gerações. Além disso, a nova unidade hospitalar de atendimento materno-infantil da capital amazonense proporcionará mais .

A universal testing machine consists of two main parts : Loading Unit. Control Unit. The arrangement of the test specimen and the exertion of the load is .A typical tensile testing machine consists of a load cell, crosshead, extensometer, specimen grips, electronics and a drive system. It is controlled by testing software used to define .A Universal Testing Machine (UTM), also known as a tensile testing machine/tester, is an electromechanical testing system that applies a tensile force to raw materials or components to test for both tensile and compressive .

TestResources manufactures and supplies universal test machines, tensile testers, dynamic testing machines, and much more. Call us today (800)430-6536. 952-944-6534 [email protected] . This part of EN ISO 13935 specifies .A UTM or universal testing machine is referred to as universal because it can be used to perform a variety of static tests, including tensile tests and compression tests, as well as flexure tests, peel tests, tear tests and other mechanical tests. .TensileMill CNC Inc. is well known for manufacturing top-tier tensile specimen preparation machines, we take pride in also offering cutting-edge tensile testing equipment that complies with the latest international standards. We achieve this by partnering with leading manufacturers of tensile testing equipment in the United States and around .An earlier name for a tensile testing machine is a tensometer. The "universal" part of the name reflects that it can perform many standard tests application on materials, components, and structures (in other words, that it is versatile). Electromechanical and Hydraulic Testing System

Measure force and displacement for various materials as they are stretched, compressed, sheared, or bent. Investigate material properties including Young’s Modulus, Tensile Strength, Yield Strength, Ductility and Modulus of Resilience. The Materials Testing Machine measures force with a 7100 N load cell and displacement with an optical encoder. Introduction Importance of Tensile Testing Machines in Material Analysis Tensile testing machines play a vital role in evaluating the strength and durability of materials across industries. Whether it’s determining the tensile strength of metals, plastics, textiles, or other materials, these machines provide essential data for product development and quality control. . If you’re serious about engineering the things you build, you need to know the limits of the materials you’re working with. One important way to characterize materials is to test the te.Key Components of a Universal Testing Machine. To understand how a universal testing machine operates, we first need to become familiar with its key components. The main components are as follows: 1. Load Frame. The load frame provides the UTM's structural backbone. It houses all the moving parts and provides machine stability during testing.

Method A is based on the increase in tensile stress during load application. In the linear elastic part of the tensile test, that is at the very beginning of the test, the rate of stress application must be between 1.15 and 11.5 MPa/sec (this corresponds to 10000 and 100000 psi/min).; However, it is clearly stated in ASTM E8 and ASTM E8M that these specifications and method do not .The tensile testing machines of the inspekt series. Inspekt - the name represents what the universal testing machines of this series are designed to do - namely, test materials, parts and components. In order to meet the requirements of every material and every component, different models of the inspekt testing machines have been developed.

Tensile testing with strain measurement techniques that can determine critical material properties including elastic modulus, tensile strength, elongation at break, and Poisson’s ratio. MTS provides testing systems, mechanical testing systems, simulation systems and sensing solutions to researchers, developers and manufacturers worldwide. Tensile testing hinges on the availability of these expertly machined specimens, typically fashioned in two styles: flat (dog bones) and round. Each design caters to different testing requirements and material types. The correct foundational process of tensile testing cannot be carried out without specially prepared specimens. In the automotive industry, tensile strength testers are used to test the tensile strength and fatigue resistance of various parts, including engine components, chassis, and safety features. In the construction industry, tensile testing machines are used to assess the strength and durability of building materials such as concrete, steel, and .

A universal testing machine consists of two main parts : Loading Unit; Control Unit; The arrangement of the test specimen and the exertion of the load is held in the loading unit.The variations in the application of the load and the .Maxtest testing software, integral to the Servo Hydraulic Universal Testing Machine 2000kN, is a versatile platform compatible with a diverse range of material testing machines. Whether you're dealing with electromechanical . With a stamped metal part, we measure a length-of-line increase over some reference distance, possibly over the full blank or in between two features. . The dogbone is held in place by top and bottom grips attached to .

Universal Testing Machines (UTMs) are multipurpose devices used to evaluate materials' mechanical properties, including tensile, compression, bending, and shear strengths. These machines are indispensable in many industries, from manufacturing to research, making certain that materials comply with necessary standards and specifications.

A laboratory-scale hand driven bench top tensile testing machine, 20kN capacity. View. Add to My Quote. BRINELL HARDNESS TEST SET. SM1002C - Experiment A set of parts for use with TecQuipment's SM1002 Bench top Tensile Test Machine to allow students to perform a simple Brinell hardness test on a range of basic engineering materials. View.NextGen Material Testing provides you with a complete range of Universal Testing Machines, also known as a tensile tester. A universal testing machine is used to test different materials for tensile stress, compression strength, bending and other mechanical properties of a .

Instron universal testing systems have a force range of 0.02 N to 2000 kN for performing mechanical tests, including tensile, compression, bend, peel, tear, friction, and more.

Tensile or universal testing machines (UTM's) are used to determine physical (mechanical) material properties and to perform material/component testing. The two main parameters are force and length, as a change of dimension (length) as force is applied. . With rotationally symmetrical force introduction parts or sample holders it is possible . Measurement of Load and Displacement. All testing systems have some sort of “loading train”, of which the sample forms a part.This “train” can be relatively complex - for example, it might involve a rotating worm drive (screw thread) somewhere, with the force transmitted to a cross-head and thence via a gripping system to the sample and then to a base .Tensile Testing machine. To check properties of Tensile & elongation as per ASTM D 638 / ASTM D 882 & ISO 527 standards. This equipment will have additional built-in programs for Peel, Bond, Cyclic endurance based on time, counts, load and extension with auto stop & .

Intelligent Tensile Tester department Store

ISO 7500-1: Metallic materials — Calibration and verification of static uniaxial testing machines — Part 1: Tension/compression testing machines — Calibration and verification of the force-measuring system. (This standard includes calibration of load cells.) ASTM E4: Standard Practices for Force Verification of Testing Machines.A laboratory-scale hand driven bench top tensile testing machine, 20kN capacity. PDF datasheet. Quantity. Add to My Quote OR CALL US TO DISCUSS +44 1159 722 611. . A set of parts for use with TecQuipment's SM1002 Bench top Tensile Test Machine to allow students to perform a simple Brinell hardness test on a range of basic engineering materials.The test is made by gripping the ends of a suitably prepared standardised test piece in a tensile test machine and then applying a continually increasing uni-axial load until such time as failure occurs. . Part 2 of this series on mechanical testing will cover welding procedure approval tensile testing. This article was prepared by Gene Mathers.

tensile testing tools

tensile testing system

CADASTROU.INSTALOU 朗 A Ora Telecom chegou para turbinar as suas férias com muita diversão com a melhor conexão! 朗 Então corre e venha ser Ora.

parts of tensile testing machine|tensile testing machines